1-2 Construction of pneumatic system

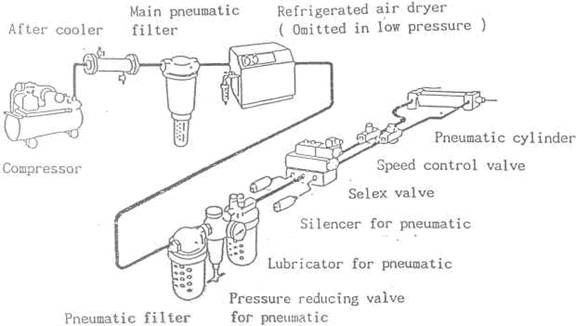

Pneumatic system is composed of 6 ~ 10 different components, which are connected systematically like Figure 1-1.

Figure 1-1 Construction of pneumatic system

1) Compressor: Compressor is equipment which transforms mechanical or electrical energy into pneumatic and classified according to size small, middle, large. It is general to generate 7~ 8Kgf/cm2 pneumatic and over 10Kgf/cm2 of generating pneumatic needs being aware of how to manage high pressure gas.

2) After cooler: In case the pneumatic of high temperature enters the equipment, troubles occur on account of flame and drain of seal materials of various kinds. After cooler is equipment which cools compressed air by water cooling or air cooling, and removes drain, etc.

3) Main-line air filter: The air which is compressed by compressor, contains dust, vapor, heated oil, etc. Main-line air filter is set up in order to remove them.

4) Refrigerated air dryer: In case pneumatic contains vapor», if this vapor is cooled down to normal temperature, the vapor is condensed into water in vent port of solenoid valve. Refrigerated air dryer is equipment which removes water of piping system that is come from vapor in compressed air by force in order to not condense vapor into water in equipment by means of dryer compressed air. (The dewing point 22°C) This system can be omitted under low pressure system.

5) Air filter: Air filter is an apparatus which removes dust and rust, and protect the using equipment from trouble. The compressed air that does not go through refrigerated air dryer does not remove drain, dust and rust in piping system.

6) Regulator for pneumatic: The compressed air that comes out of compressor has a little high pressure. This device regulates the pneumatic pressure in order to make it stable.

7) Lubricator for pneumatic: This device delivers lubricating oil by Using the flow of pneumatic in order to make smoothly operation smooth and improve the durability of using equipment.

- The functions 5~7 are mostly made up of one unit combination set.

8) Silencer for pneumatic: It makes a vent noise at the vent port when the selex valve is changed over. This device reduces such vent noise and removes noise pollution.

9) Selex valve (Solenoid valve): This device opens and shuts pneumatic or changes over the flow-direction by electrical signal, etc. The piston rod of pneumatic cylinder is used as controller of extending and retracting in Figure 1-1.

10) Speed control valve: This device controls the speed of piston rod of pneumatic cylinder by controlling the flow of pneumatic.

11) Pneumatic cylinders: This device transforms the energy of compressed air into needed power and movement. Generally a double acting cylinder holds the majority.

|